Shop Premium Used Ice Equipment | Industrial-Grade Solutions

- Specifications

- FAQs

Frequently Asked Questions

Commercial ice equipment, such as ice makers, freezers, and chillers are essential to numerous industrial applications. Industries such as food and beverage, healthcare, and hospitality need a steady supply of ice for preserving, cooling, or even displaying products.

Having commercial ice equipment ensures consistent quality and hygiene standards. Your company must also adhere to strict health and safety regulations. Ice equipment is designed with advanced filtration systems to remove impurities and contaminants which result in clean and pure ice production. Investing in industrial ice machines and equipment will ensure reliable supply, consistent quality, cost savings, and safety.

Some commercial ice makers and other equipment will require a drain. This is because ice machines generate a significant amount of water during the ice-making process. The drain prevents water from accumulating and causing damage near the equipment.

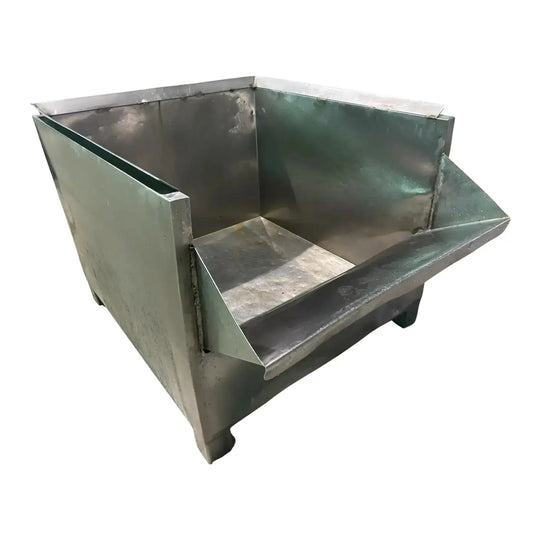

If you're interested in investing in industrial ice equipment, you will need to figure out what type of ice is best for your company or application needs. There's flake ice, tube ice, ice cubes, nugget ice, and more. Then, you can choose your ice machine or ice maker depending on the ice type. Don't just go with the popular choice; determine size and capacity, functionality, as well as energy efficiency. You'll also need an ice storage bin or storage unit for your industrial facility. Moreover, you will need refrigeration equipment in conjunction with your ice maker such as freezers and chillers.

Yes. Industrial-grade ice equipment will need maintenance. The meticulous upkeep of water filtration units is a cornerstone in ensuring the unabated reliability of ice machines in your facility. Regular maintenance checks, aligned with manufacturer guidelines, act as preventative measures, averting potential disruptions that could impede service and tarnish customer experiences.

Adhering to a structured schedule for filter replacements is a non-negotiable practice for maintaining water quality and safety for your ice maker. Depending on usage rates and water conditions, replacement intervals might vary, emphasizing the need for vigilant oversight and timely action to sustain impeccable service standards. This is necessary regardless of whether you use ice equipment for food displays, temperature control, or other functions.

Top Sellers

View all